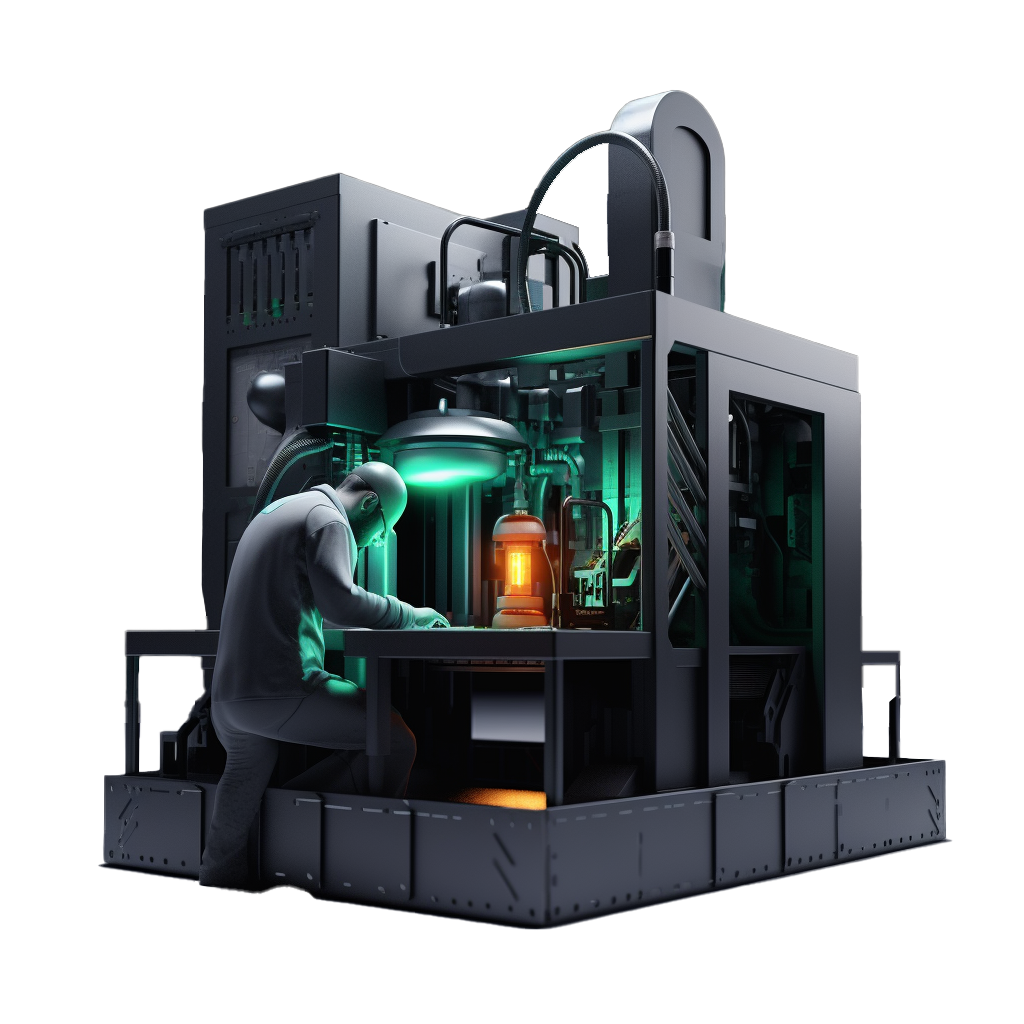

Steel 3D printing - the revolution in manufacturing technology

Your expert for precise and efficient steel 3D printing solutions

Explore the wide range of possibilities offered by steel 3D printing and transform your manufacturing processes. With our advanced technology and qualified team, we are well equipped to realize your projects with the highest precision and quality.

Customer extract:

Why steel in 3D printing?

The advantages of steel 3D printing

Steel is a material that is valued for its robustness and versatility in many industries. But did you know that steel also has excellent properties in 3D printing? In this section, we would like to highlight the numerous advantages of steel 3D printing that make this material an excellent choice for a variety of applications.

Robustness and durability

One of the most important features of steel 3D printing is its robustness. Compared to other materials such as aluminum or plastic, steel offers high strength and durability, making it ideal for demanding applications.

Corrosion resistance

Steel variants such as stainless steel are corrosion-resistant, which makes steel 3D printing particularly suitable for applications in harsh or damp environments. With steel 3D printing, you can produce components that are durable and resistant.

Precision and versatility

The precision that can be achieved with steel 3D printing is impressive. This enables the production of complex and detailed components that would be difficult using conventional manufacturing methods.

Broad applicability

Steel is a versatile material that is used in a range of industries. Whether in mechanical engineering, the automotive industry or construction - the possibilities for steel 3D printing are wide-ranging.

Industrial automation

Steel 3D printing is playing an increasingly important role in industrial automation. Thanks to the ability to produce precise and robust components for machines and systems, this technology helps to increase efficiency and optimize processes.

Cost efficiency

Although steel is a robust and durable material, steel 3D printing enables cost-efficient production. Costs can be significantly reduced compared to traditional manufacturing methods, especially when producing small batches or complex components, making steel 3D printing an economically viable option.

Download whitepaper

The future of steel 3D printing: efficient production, high-quality components and innovative applications

Innovation meets precision

Technology and processes in steel 3D printing

Immerse yourself in the world of steel 3D printing and discover a wide range of advanced technologies that offer you precise and robust components for your projects.

Selective laser melting (SLM)

SLM (Selective Laser Melting) is the cutting-edge technology in steel 3D printing that enables complex components with impressive strength.

Metal Binder Jetting (MBJ)

MBJ (Metal Binder Jetting) is revolutionizing steel 3D printing, offering excellent surface quality and efficient mass production options.

Metal SLS (Selective Laser Sintering)

Metal SLS (Selective Laser Sintering) enables the precise production of steel components with a high level of detail and robustness.

Metal FDM (Fused Filament Fabrication):

Metal FDM (Fused Filament Fabrication) with special steel filaments offers a cost-effective and fast solution for prototypes and smaller projects in steel 3D printing.

Directed Energy Deposition (DED):

DED (Directed Energy Deposition) is characterized in steel 3D printing by its ability to produce extremely detailed and complex components.

Metal lithography

Metal lithography offers the possibility of creating impressive details and complex structures in steel 3D printing.

Cold Spray

Cold spray technology in steel 3D printing enables the production of precise and complex components through the use of cold metal.

Wire Arc Additive Manufacturing (WAAM)

WAAM (Wire Arc Additive Manufacturing) offers a cost-effective and fast solution for prototypes and smaller projects in steel 3D printing.

Electron beam melting (EBM)

Electron beam melting is also an advanced method in steel 3D printing, particularly suitable for applications that require high temperature and corrosion resistance.

Quality control and post-processing

After the printing process, we subject all stainless steel 3D printed products to strict quality control and offer various post-processing options to achieve the best possible result.

Areas of application for steel 3D printing

Where progress meets versatility

Steel 3D printing is not only a groundbreaking technology, but also a versatile tool that can be used in various industries and for a wide range of applications. In this section, we explore the many applications of steel 3D printing that make it an ideal choice for a wide range of projects.

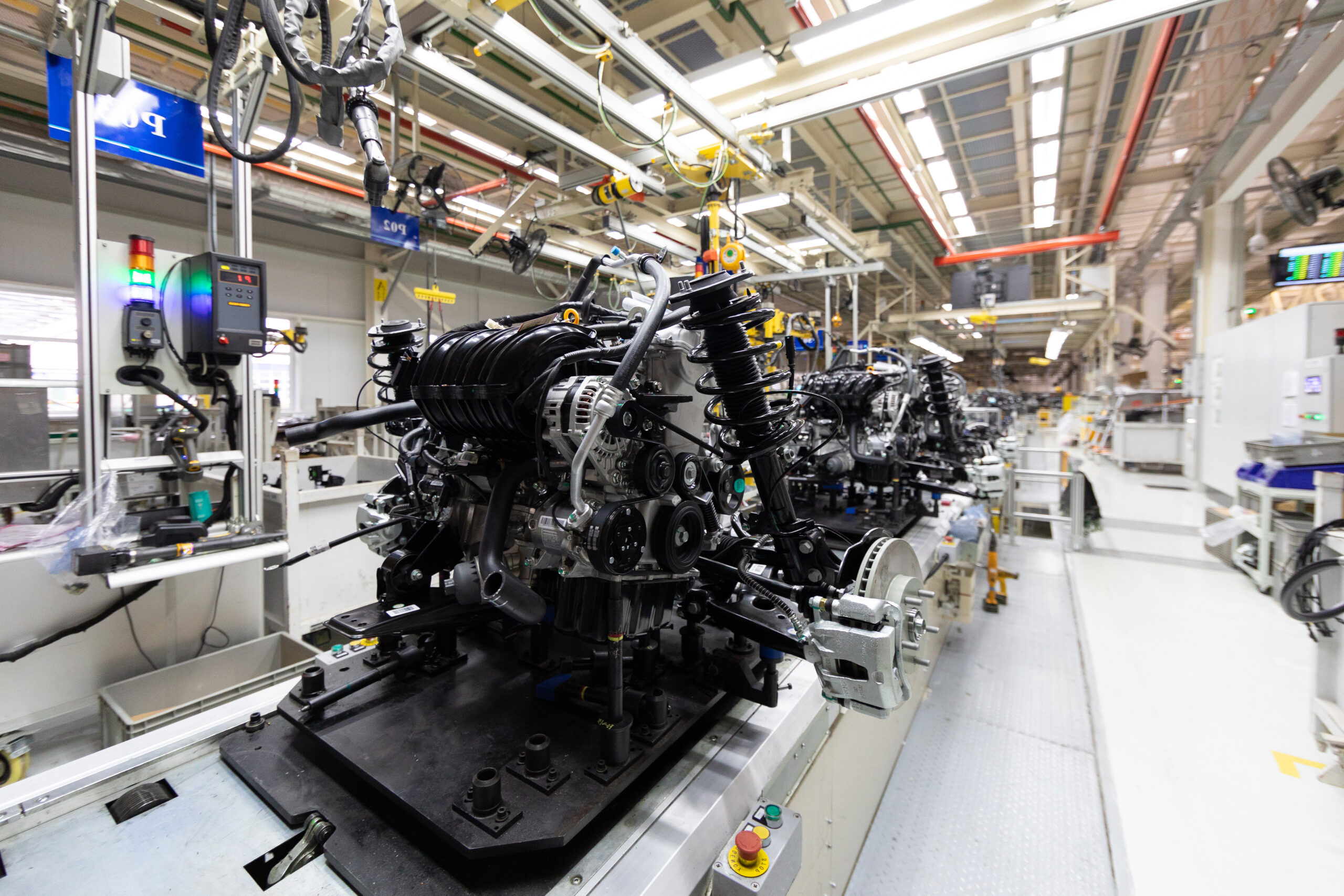

Automotive industry

In the automotive sector, steel 3D printing enables the production of robust and durable components, from engine components to chassis parts.

Aerospace

Steel 3D printing offers a cost-effective way to produce high-strength and precise components for aerospace applications, such as engine parts or satellite components.

Medical technology

Steel 3D printing is used in medical technology for the production of surgical instruments and medical devices that have to meet high standards of strength and precision.

Building industry

In the construction industry, steel 3D printing can be used for the production of specialized construction elements such as connecting elements or complex load-bearing structures.

Energy sector

In the field of renewable energies, steel 3D printing offers solutions for the production of durable and corrosion-resistant components in wind turbines and solar plants.

Industrial manufacturing

Steel 3D printing is increasingly being used in industrial manufacturing to produce complex components and tools that would be difficult or expensive to produce using traditional methods.

For buyers & customers

Technical information about our steel 3D printing service

For a successful and efficient collaboration in the field of steel 3D printing, you should consider the following points:

Secrecy

We guarantee the highest level of confidentiality in the realization of your steel 3D printing projects.

Data formats

We accept various data formats for steel 3D printing, including STL, OBJ and STEP.

Requirements

Please make sure that your design files meet the specific requirements for steel 3D printing. This is crucial for the quality and functionality of the end product.

AGBs

You can view our general terms and conditions for steel 3D printing on our website at any time. They contain important information on cooperation and services in the field of steel 3D printing.

Customer ratings

What our customers say about our steel 3D printing service

Your satisfaction is our top priority. Find out what our customers have to say about the quality and reliability of our steel 3D printing service.

FAQ - Frequently asked questions about titanium 3D printing

Do you have questions about titanium 3D printing? Here you will find answers to the most frequently asked questions about our titanium 3D printing service.

Your contact persons

Ready for your breakthrough with 3D printing? Do you have any questions or need more information? Feel free to contact us, we are always at your disposal.

Jörg Willmann

Managing Director

- Joerg.Willmann@additive-willmann.de

- +49 7654 - 681 400-1

- Talstraße 7 | 79843 Löffingen

Carina Willmann

Key Accounting & Marketing

- Carina.Willmann@additive-willmann.de

- +49 7654 - 681 400-2

- Talstraße 7 | 79843 Löffingen