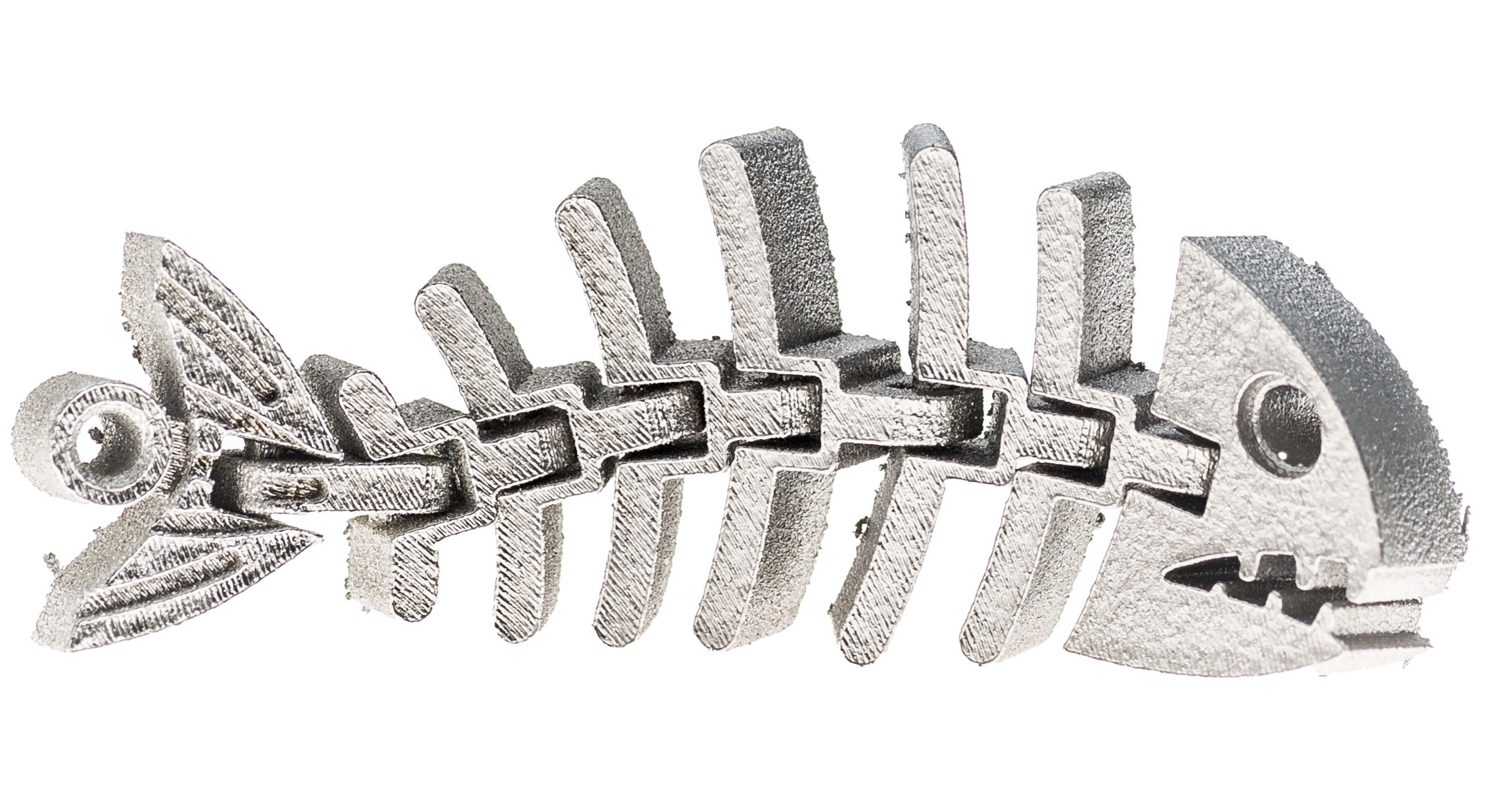

3D printing in metal - All the information you need to revolutionize your production

3D printing metal materials

Discover the limitless possibilities of metal 3D printing technology. From titanium to stainless steel, our diverse material options offer the perfect solution for every project. Increase efficiency, quality and innovation with our cutting-edge 3D printing processes. Your dream project is just a print away!

Customer extract:

Titanium

3D printing

Ideal for lightweight but extremely resilient components, often used in aerospace and medical technology.

Aluminum

3D printing

Known for its lightness and good thermal conductivity, it is particularly suitable for automotive and electronics applications.

Steel

3D printing

Provides a robust and cost-effective solution for components that have to withstand high loads.

Stainless steel

3D printing

Ideal for applications that require high corrosion resistance and aesthetic surface quality.

Why 3D print metal?

Advantages for your company

Jörg Willmann

Founder, CEO of Additive Willmann

Faster production and time-to-market

Complex geometries and design freedom

Cost and material savings

Download whitepaper

The future of 3D printing in metal: efficient production, high-quality components and innovative applications

Wide range of materials

Materials in 3D printing metal

Steel

A versatile and robust material that is used for a wide range of applications in metal 3D printing.

Aluminum

A lightweight and corrosion-resistant material that is ideal for applications where weight reduction and heat dissipation are important.

Titanium

A material with high strength and low weight that offers excellent properties for demanding applications in metal 3D printing.

Stainless steel

A corrosion-resistant material that is characterized by its durability and versatility in metal 3D printing.

Copper

A material with excellent electrical conductivity that is ideal for 3D printing metal applications where good heat dissipation is required.

Your contact persons

Ready for your breakthrough with 3D printing? Do you have any questions or need more information? Feel free to contact us, we are always at your disposal.

Jörg Willmann

Managing Director

- Joerg.Willmann@additive-willmann.de

- +49 7654 - 681 400-1

- Talstraße 7 | 79843 Löffingen

Carina Willmann

Key Accounting & Marketing

- Carina.Willmann@additive-willmann.de

- +49 7654 - 681 400-2

- Talstraße 7 | 79843 Löffingen