Highest quality, fast production, limitless possibilities

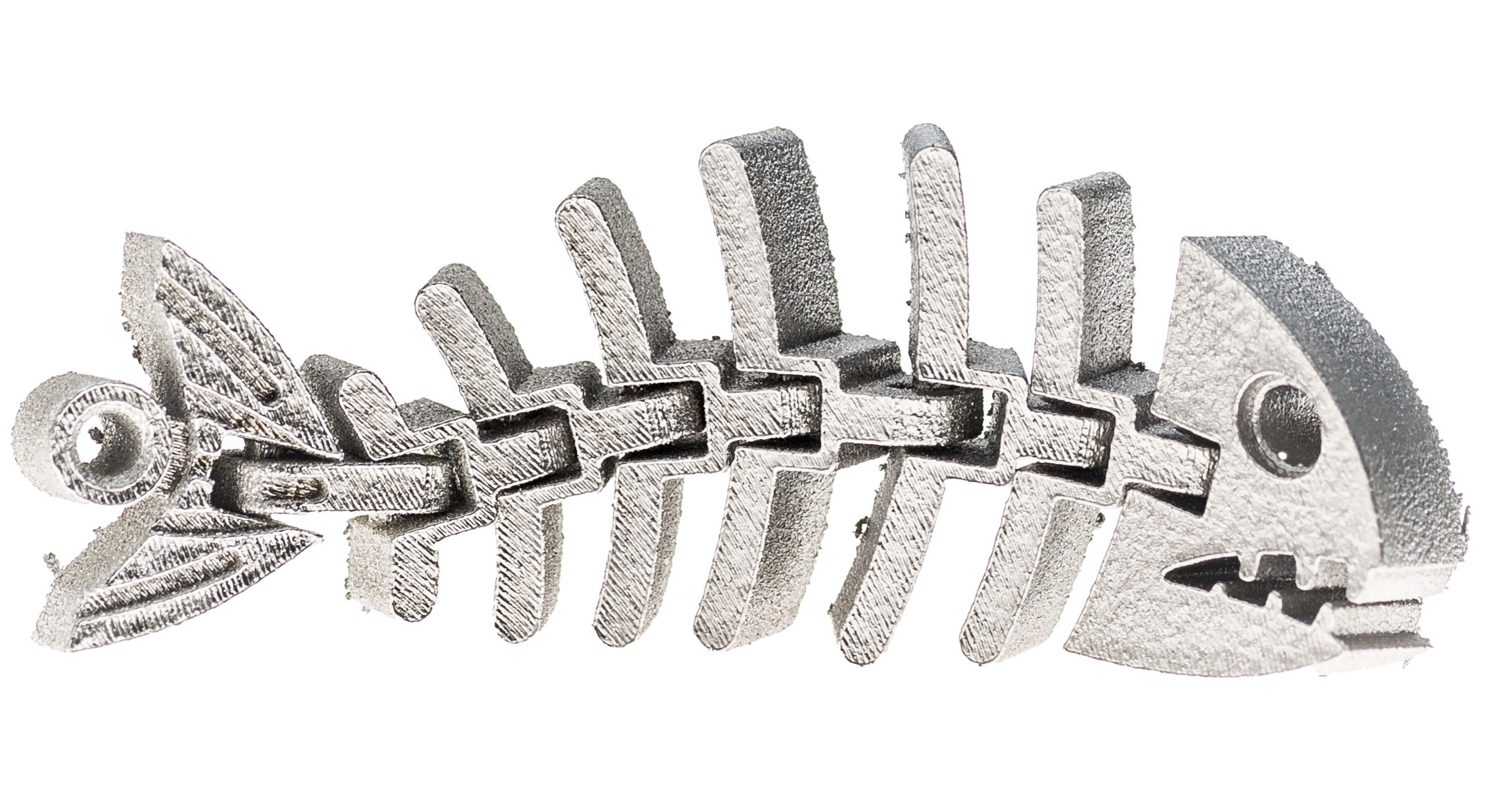

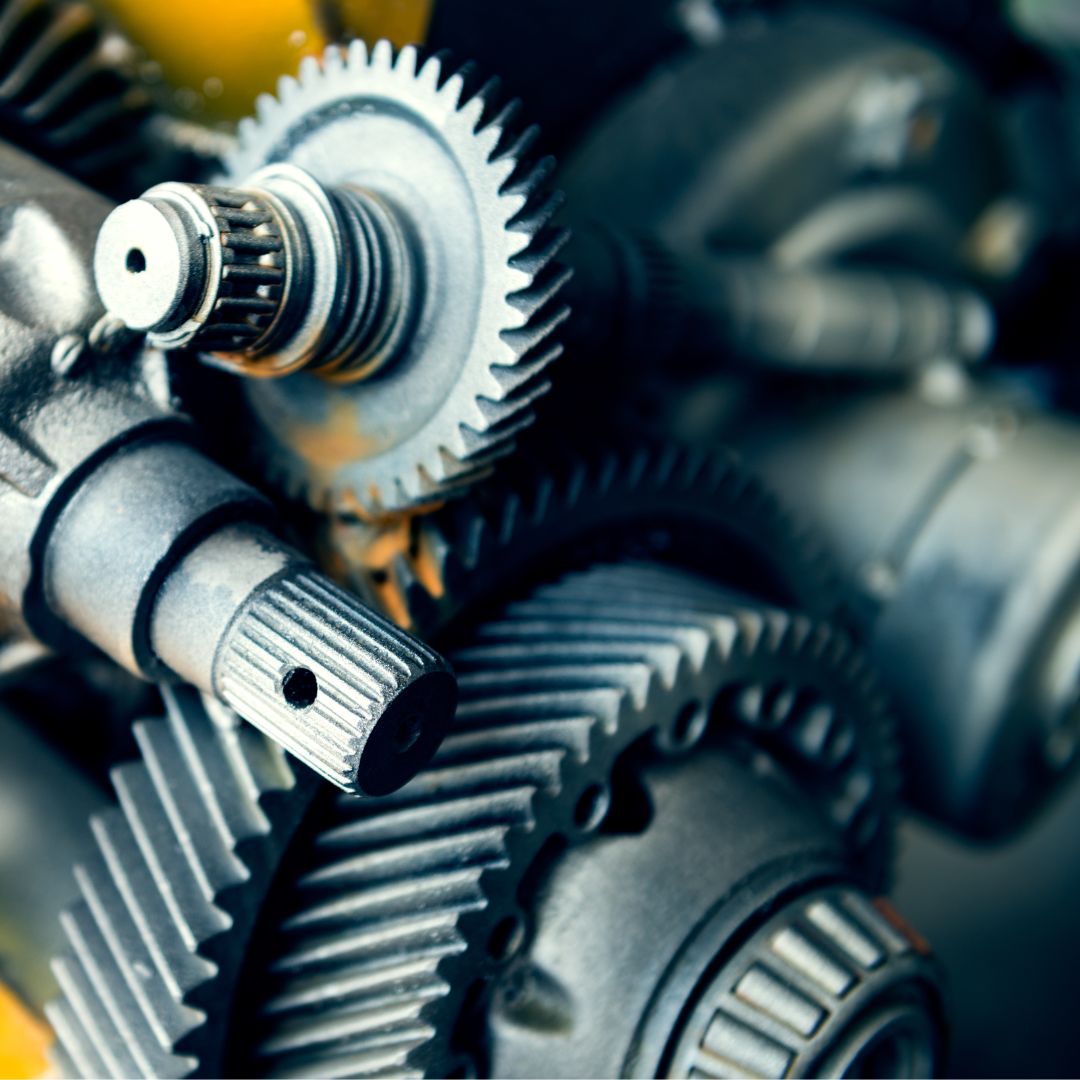

Cold Spray (Multi Material) technology: Precise metal production for your requirements

We help companies to produce high-quality components using the cold spray process to increase their efficiency and productivity without compromising on quality.

Customer extract:

Why Cold Spray (Multi Material)?

High assembly speed and material variety

From precise prototypes to series production, we offer you first-class solutions.

The cold spray process is characterized by a high build-up speed and a wide range of usable materials. Find out how you can benefit from this innovative technology.

"Discover the benefits of the cold spray process and how it allows you to build components quickly and use a variety of materials."

Jörg Willmann

Founder, CEO of Additive Willmann

Advantages of the Cold Spray (Multi Material)

Fast assembly and variety of materials

Download whitepaper

The future of 3D printing in metal: efficient production, high-quality components and innovative applications

Wide range of materials

Materials in cold spray technology

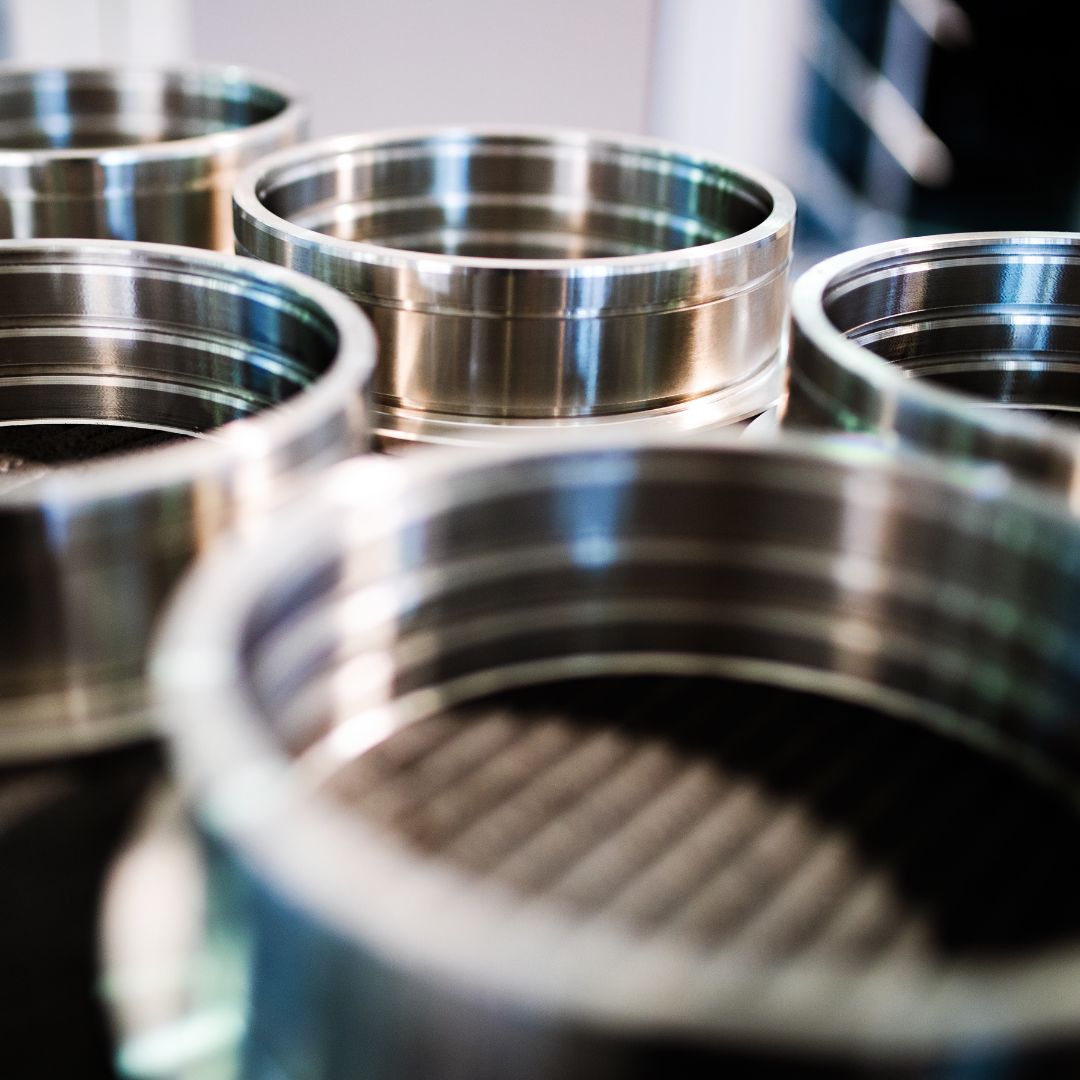

Stainless steel

Stainless steel offers high corrosion resistance and strength, making it ideal for applications in the food industry, medical technology and construction.

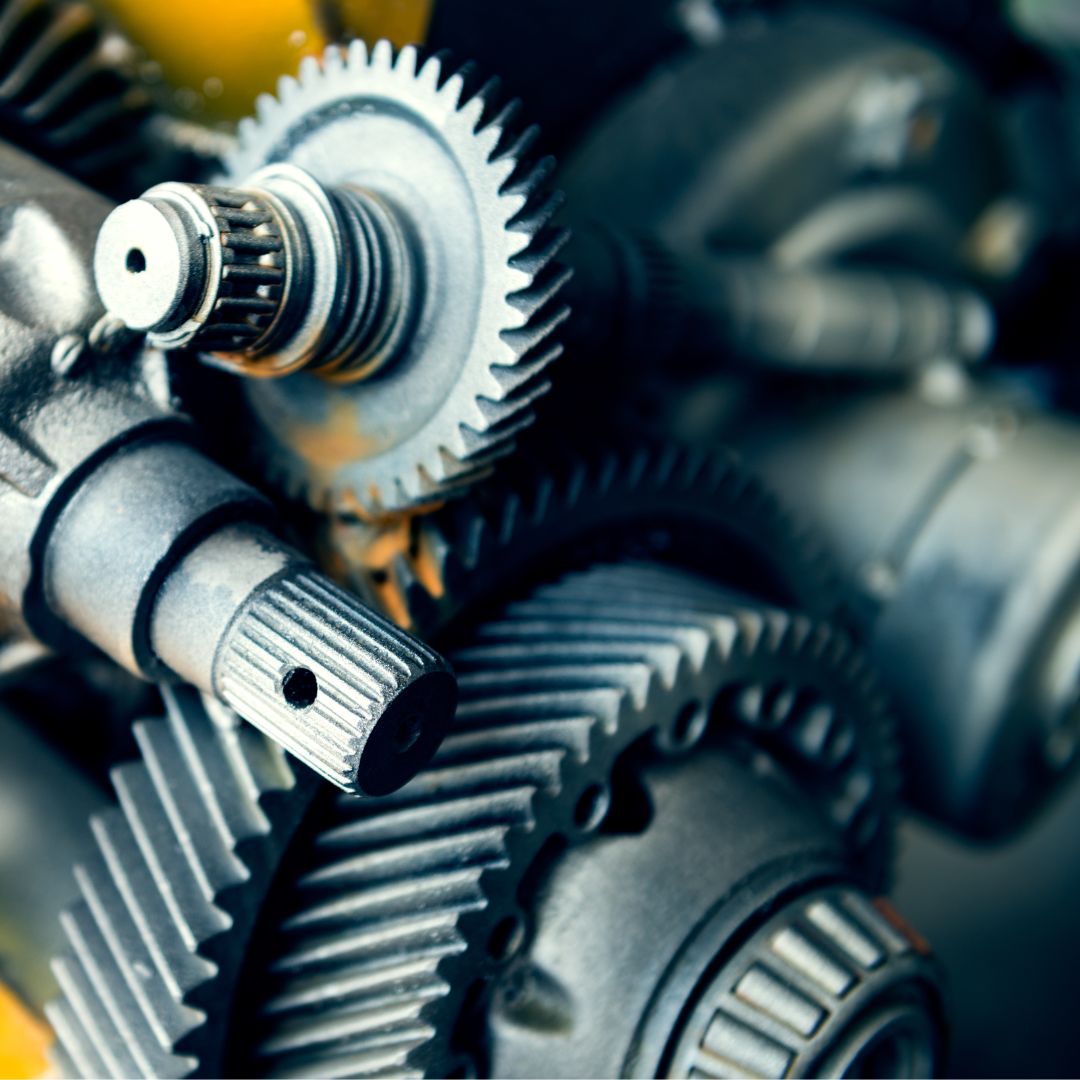

Tool steel

Tool steels in the cold spray process - Tool steels in the cold spray process are indispensable for the production of high-precision coatings. These coatings offer excellent wear resistance and durability, making them ideal for demanding applications where tools and components need to be optimally protected.

Copper

Copper in the cold spray process - Copper is used in the cold spray process to coat surfaces with high thermal conductivity and electrical conductivity. These coatings are of great importance in the electronics and electrical industry as they help to improve the efficiency and performance of components.

Why we should talk

Our services in Cold Spray (Multi Material)

Customized solutions for your requirements

Find out more about our customized services in the cold spray process and how we can support you in realizing your projects.

Areas of application for cold spray technology

Industries and products

Metal 3D printing is ideal for a variety of applications, including automotive, aerospace, medical and many more. Here are some examples of how cold spray technology is used in these industries:

Aerospace

Production of lightweight components, turbine components, satellite structures

Medical technology

Production of lightweight components, turbine components, satellite structures

Automotive industry

Engine components, body components, prototypes

Lightweight construction, prototype production

Mechanical engineering

Complex components, wear parts,

tools

Energy

Turbine blades, components for renewable energy systems

Architecture & Design

Architectural models, customized design objects

Electronics

Enclosures for electronic components,

Heat sinks

Development

Prototypes for new technologies and

products

Ffor buyers & customers

Technical information

Lorem ipsum dolor sit amet, consec tetur adipis cing elit. Ut elit tellus, luctus nec ullam corper mattis, pulvinar dapibus leo.

Secrecy

Lorem ipsum dolor sit amet, consec tetur adipiscing elit. Ut elit tellus, luctus nec ullam corper.

Data formats

Lorem ipsum dolor sit amet, consec tetur adipiscing elit. Ut elit tellus, luctus nec ullam corper.

Requirements

Lorem ipsum dolor sit amet, consec tetur adipiscing elit. Ut elit tellus, luctus nec ullam corper.

AGBs

Lorem ipsum dolor sit amet, consec tetur adipiscing elit. Ut elit tellus, luctus nec ullam corper.

Technical data of the cold spray technology

Quality in Cold Spray (Multi Material) technology

Our quality management ensures compliance with high standards and the delivery of components of first-class quality. We rely on precise process control to achieve the desired results.

Our advanced cold spraying technology enables us to manufacture components from a variety of materials. With exceptional precision and attention to detail, we are able to produce complex components. Whether you want to develop prototypes or run series production, our technology ensures consistently high quality and performance.

We understand that every industry has specific requirements. That's why we offer customized solutions that are tailored to your exact needs. Our experts work closely with you to understand your individual requirements and develop innovative solutions that exceed your expectations.

Frequently asked questions about Cold Spray (Multi Material) technology

The cold spray process is an additive manufacturing process in which fine particles are applied to a surface at high speed to form a layer.

The cold spray process enables the use of a wide range of materials, including metals, alloys and composites.

The advantages of the cold spray process include a high build-up speed, the use of a variety of materials, low heat exposure and good adhesion properties between the layers and the substrate.

The cold spray process is suitable for applications such as repair and restoration of components, surface protection, coatings, composite production and more.

The accuracy of cold spray depends on various factors, including the materials selected and the process parameters. However, high dimensional accuracy can be achieved.

Your contact persons

Ready for your breakthrough with 3D printing? Do you have any questions or need more information? Feel free to contact us, we are always at your disposal.

Jörg Willmann

Managing Director

- Joerg.Willmann@additive-willmann.de

- +49 7654 - 681 400-1

- Talstraße 7 | 79843 Löffingen

Carina Willmann

Key Accounting & Marketing

- Carina.Willmann@additive-willmann.de

- +49 7654 - 681 400-1

- Talstraße 7 | 79843 Löffingen